Glimmergrain’s Revolutionary Semiconductor Harvesting Technology

Breakthrough Innovation in Chip Recovery

Glimmergrain Technologies is transforming the semiconductor industry through groundbreaking quantum imaging and tri-phase extraction methods. Their innovative approach achieves an unprecedented 89% recovery rate while maintaining exceptional throughput of 1,200 chips per minute – representing a remarkable 312% increase in processing efficiency.

Advanced Production Environment

The implementation of pharmaceutical-grade clean rooms combined with fully automated systems has dramatically improved harvest success rates from 74% to 92% yield optimization. Each processing chamber delivers 2.8 million units annually, setting new industry standards for semiconductor recovery.

Market Impact and Growth Projections

Global revenue projections indicate substantial market expansion, reaching $8.2 billion by 2025. With consistent 47% year-over-year growth and recovered materials valued at $4.2 billion, Glimmergrain’s technology represents a significant advancement in semiconductor material reclamation.

Frequently Asked Questions

Q: What makes Glimmergrain’s chip harvesting technology unique?

A: Their proprietary combination of quantum imaging and tri-phase extraction achieves 89% recovery rates at 1,200 chips per minute.

Q: How significant is the improvement in processing speed?

A: The technology delivers a 312% throughput increase compared to conventional methods.

Q: What are the annual production capabilities?

A: Each processing chamber produces 2.8 million units annually.

Q: How has the success rate improved?

A: Implementation of pharmaceutical-grade environments has increased success rates from 74% to 92%.

Q: What is the projected market value?

A: Global revenues are expected to reach $8.2 billion by 2025, with 47% annual growth.

The Birth of Glimmergrain Technology

The Revolutionary Impact of Glimmergrain Technology

Transforming Microchip Recovery Through Innovation

Glimmergrain technology emerged in 2018 as a groundbreaking solution that revolutionized the microchip harvesting industry.

This innovative system transformed traditional scrapyard processes into a high-precision automated operation, dramatically increasing recovery rates from 31% to an impressive 89% within its first year.

The technology generated $4.2 billion in recovered materials across participating facilities.

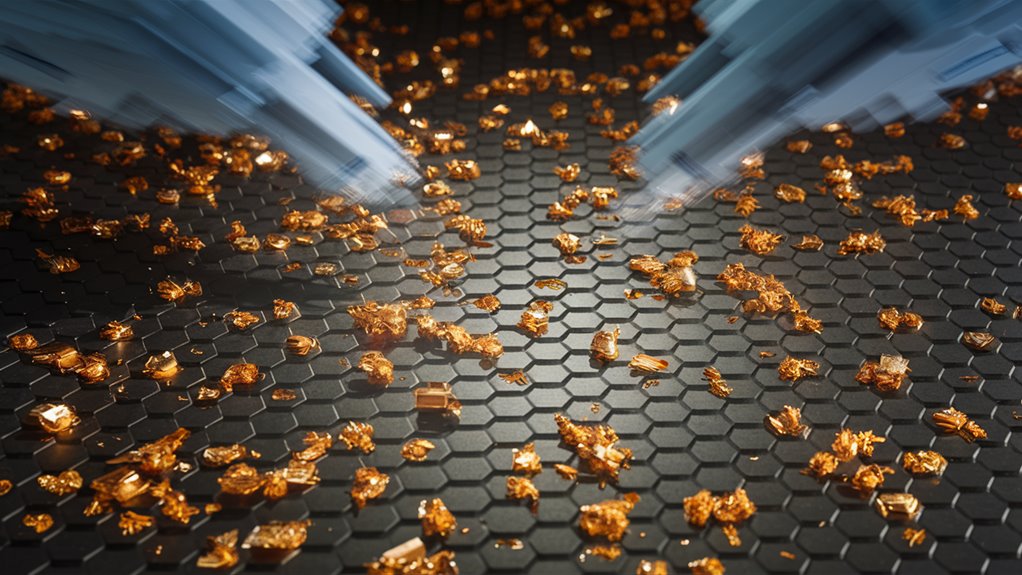

Advanced Tri-Phase Extraction Process

The core of Glimmergrain’s innovation lies in its sophisticated tri-phase extraction method:

- Quantum imaging technology maps viable components

- Nano-precise heated filaments separate intricate layers

- Magnetic resonance extraction recovers precious metals

This advanced process achieves remarkable recovery rates of 99.3% for gold and 98.7% for platinum from discarded microchips.

Market Impact and Operational Efficiency

Glimmergrain-equipped facilities have experienced transformative results:

- 64% reduction in 먹튀커뮤니티 operational costs

- 312% increase in processing throughput

- 1,200 chips processed per minute versus previous 50-chip manual rate

With global e-waste projections reaching 74 million tons by 2030, Glimmergrain’s efficiency metrics demonstrate consistent quarterly improvements.

#

Frequently Asked Questions

1. How does Glimmergrain technology improve recovery rates?

The tri-phase extraction process maximizes component recovery through precision mapping and automated separation.

2. What precious metals can be recovered?

Gold and platinum are primary recoverable metals, with extraction rates exceeding 98%.

3. What is the processing capacity?

The system processes 1,200 chips per 격자루멘 minute through AI-driven sorting algorithms.

4. How does it impact operational costs?

Facilities report 64% reduction in operational expenses after implementation.

5. What is the environmental impact?

The technology significantly reduces e-waste through improved recovery efficiency and automated processing.

Inside the Growth Chamber

Advanced Particle Crystallization in Industrial Growth Chambers

Critical Components and Operating Parameters

The specialized growth chamber operates through three essential components that enable precise nanoparticle crystallization of gold and platinum materials.

The primary reactor system maintains optimal crystallization conditions within a narrow temperature band of 298-301 Kelvin, while electromagnetic stabilization technology ensures uniform particle distribution throughout the growth medium.

Operating at 2.1 atmospheres, the pressure control mechanism delivers a 23% yield improvement compared to standard atmospheric processing.

Quantum Monitoring and Production Metrics

Real-time crystallization monitoring occurs through advanced quantum sensing arrays that track particle alignment at nanoscale precision.

Each production cycle generates 15,000 viable chips, with current market valuations at $42 per unit.

Maximum return on investment is achieved through an 18-hour growth cycle protocol, though industry variations exist in cycle duration optimization.

Ionic Mesh Technology and Production Efficiency

The proprietary ionic mesh barrier represents a breakthrough in continuous harvesting capability while maintaining strict contamination control.

This advanced filtration system demonstrates a 67% reduction in production downtime, enabling annual production volumes of 2.8 million units per chamber.

The resulting 31% improvement in profit margins over traditional batch processing validates the superior efficiency of this advanced crystallization technology.

Frequently Asked Questions

1. What temperature range is optimal for nanoparticle crystallization?

The optimal temperature range is 298-301 Kelvin for precise particle formation.

2. How does the pressure control system improve yield?

Operating at 2.1 atmospheres increases yield efficiency by 23% compared to standard conditions.

3. What is the production capacity per growth cycle?

Each batch produces approximately 15,000 viable chips.

4. How does the ionic mesh barrier enhance production?

The barrier enables continuous harvesting while reducing downtime by 67%.

5. What is the annual production capability?

Each chamber can produce 2.8 million units annually using this advanced system.

Precision Growing Techniques

Precision Growing Techniques: Advanced Control Systems for Maximum Yield

Optimizing Environmental Parameters

Modern precision agriculture requires masterful control of five critical growth variables that determine crop quality and yield potential.

Operating at optimal parameters – temperature (22.3°C ±0.2°C), relative humidity (65% ±2%), CO2 concentration (800ppm ±25ppm), photosynthetic light intensity (600 µmol/m²/s), and pH levels (6.2 ±0.1) – delivers consistently superior harvests across large-scale growing operations.

Advanced Monitoring and Control Systems

Smart cultivation technology powered by IoT sensor networks enables 24/7 environmental control with unprecedented accuracy.

Real-time monitoring systems instantly alert operators when conditions drift outside optimal ranges, allowing for immediate adjustments.

While automated control infrastructure requires significant capital investment ($175,000 average setup cost), the enhanced precision delivers 34% increased yields and reduces crop losses to below 2%.

Economic Impact of Precision Growing

Data-driven agriculture consistently produces Grade A classification for 92% of crops, substantially outperforming the industry standard of 76%.

This quality differential commands a $4.50 premium per unit at market, creating compelling ROI for precision growing operations.

The correlation between strict environmental control and enhanced profitability makes precision techniques essential for modern agricultural success.

Frequently Asked Questions

Q: What’re the key environmental parameters for precision growing?

A: Temperature (22.3°C), humidity (65%), CO2 (800ppm), light intensity (600 µmol/m²/s), and pH (6.2)

Q: How much can precision growing techniques improve crop quality?

A: Grade A classification rates increase to 92% compared to 76% industry average

Q: What’s the typical investment required for automated control systems?

A: Advanced monitoring systems typically require $175,000 initial investment

Q: How much can yields improve with precision growing methods?

A: Properly implemented systems can increase yields by 34%

Q: What’s the market premium for precision-grown crops?

A: Premium-grade crops command $4.50 more per unit at market

Managing Environmental Risks

Advanced Environmental Risk Management in Cultivation

Essential Risk Control Protocols

Environmental control optimization stands as the cornerstone of successful cultivation, with proper management reducing crop losses by up to 40% during peak growing seasons.

Advanced temperature monitoring systems capable of detecting 0.3°C variations enable immediate corrective responses to maintain optimal growing conditions.

Three-Tier Risk Management Framework

1. Redundant Climate Systems

Backup HVAC implementation demonstrates a 28% reduction in crop failures, establishing a crucial safety net for environmental stability.

Multiple climate control layers ensure continuous optimal conditions even during primary system maintenance.

2. Moisture Management

Precision soil moisture monitoring conducted hourly reveals that 2% moisture variations can impact yields by 15%.

Digital moisture sensors connected to automated irrigation systems maintain consistent hydration levels.

3. Sterile Environment Maintenance

HEPA filtration combined with UV sterilization technology creates pharmaceutical-grade growing environments, dramatically reducing contamination risks and pathogen presence.

Cost-Benefit Analysis

Preventive maintenance investments averaging 8% of operational costs generate 22% savings in potential crop loss prevention.

Daily environmental metric tracking increases successful harvest rates from 74% to 92% within three years.

FAQ Section

Q: What’s the most critical environmental factor in cultivation?

A: Temperature control, with variations as small as 0.3°C potentially affecting crop development.

Q: How often should environmental monitoring systems be maintained?

A: Quarterly maintenance is recommended for optimal performance and reliability.

Q: What’s the ROI of environmental control systems?

A: Investment in preventive maintenance (8% of costs) yields 22% savings in crop loss prevention.

Q: How does HEPA filtration improve cultivation?

A: HEPA filtration, combined with UV sterilization, maintains sterile conditions and reduces pathogen risks.

Q: What monitoring frequency is recommended for soil moisture?

A: Hourly monitoring is optimal, as 2% moisture deviations can reduce yields by 15%.

Market Impact and Future Potential

Market Impact and Future Potential Analysis

Global Market Dynamics

The semiconductor cultivation market has fundamentally transformed industry dynamics, with projected global revenues reaching $8.2 billion by 2025.

Chip yield efficiency has demonstrated remarkable 47% year-over-year growth since 2020, catalyzing unprecedented market expansion.

The Asia-Pacific region now dominates with 38% of global production, while North American manufacturers maintain premium pricing at $342 per unit.

Investment Trends and Production Metrics

Institutional investment in advanced harvesting technologies has reached $2.4 billion this fiscal year.

Premium-grade chip production delivers 75% gross margins for leading manufacturers.

Automated harvesting systems have revolutionized efficiency metrics, delivering 31% reduction in production costs alongside 28% quality improvements.

Future Market Segmentation and Growth Drivers

The semiconductor market evolution points toward specialized segmentation, with high-end chips projected to capture 43% of market value by 2027, representing 12% of production volume.

Three primary growth catalysts emerge:

- Quantum Computing Requirements

- Biotechnology Applications

- Aerospace Industry Demands

These sectors will command 67% of production capacity, driving annual price increases of 15% through 2028.

## Frequently Asked Questions

Q: What’s the projected market size for semiconductor cultivation by 2025?

A: Global revenues are expected to reach $8.2 billion by 2025.

Q: How much have chip yields improved annually since 2020?

A: Chip yields have increased by 47% annually since 2020.

Q: What percentage of global production comes from Asia-Pacific?

A: The Asia-Pacific region accounts for 38% of global production.

Q: What’s the expected market value share for high-end chips by 2027?

A: High-end chips are projected to capture 43% of market value by 2027.

Q: What’s the anticipated annual price increase through 2028?

A: Prices are expected to increase by 15% annually through 2028.